Despite how much it has been

covered in literature, training notes and video courses, it is impossible to

over emphasize the importance of the 5S method in a Lean Productivity System.

Why?

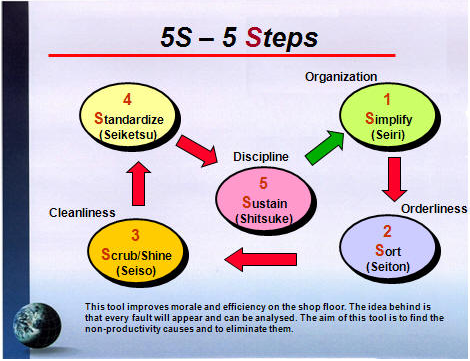

· It is at

the core of the system: Nearly every method and technique is based on one

or more aspects of the 5S method. Every process, workstation, production line

and supply center only works at top capacity if it is:

o

Sorted:

Everything not needed has been removed.

o

Set in

Order: Everything that remains is positioned for maximum efficiency and

minimum wasted motion.

o

Shined:

Dirt, debris and clutter create time wasting distractions and are a safety

hazard.

o

Standardized:

Each productivity success recorded so that it can be repeated.

o

Sustained:

Each person is constantly on the lookout for ways to improve.

· It is the

reason for much of your current success: While many intermediate and

advanced techniques can and will improve productivity, 5S leads

the way, capturing the low hanging fruit by making every work area clean, fast,

and efficient. In order for advanced productivity enhancement techniques to

work, it must have a pretty productive system to start with.

· It is

simple: 5S is easy to understand and apply, which is why everyone in the

organization should be well versed in 5S.

Here are some 5S products

from Enna that can help you to promote 5S in your operation and ingrain it into

your work culture.

· 5S

Videos: Enna has a set of 3 5S related video courses that can help you to

make 5S an integral part of your operation:

o

The

Fundamental Principles of 5S: This course goes through the basics of 5S,

including the definitions of the 5 points. It is an important tool for training

new hires and workers in areas that Lean is being introduced. It also can be

used to help management understand the importance of this core concept. Using

this as the basis of a refresher course in Kaizen events and workshops is also

recommended.

o

5S Into

Action: A professionally produced video course that tells not only how to

do 5S, but why. It goes into detail on how the principles of 5S can and do make

significant improvements to nearly any production process.

o

Advanced

Application of 5S: This course talks about the way so sustain 5S in

maturing systems, an important skill if you want to achieve the last S,

Sustainability.

· 5S

Training Packages: These products are designed to be used in Kaizen

workshop settings for skill reinforcement. They are self-contained and provide

all the materials needed for an effective and enjoyable training review

session. The packs available include:

o

5S

Training Pack: Designed to cover 5S concepts in the manufacturing

environment.

o

5S Office

Solution Pack: Designed to transfer the benefits of 5S to the front office.

o

Learning

Kits: These supplemental Quick Learning Lean Kits provide a

fast track training resource for key concepts.

· Quick

Guide: This product is a combination training packet and resource, and is

designed to be used to teach the principles of 5S and as a reference in real

world situations.

Limited Time Offer: Share Enna's

Products on Social Media and Receive 15% Off! For more details visit Enna.com.