All people take pride in their work. A lot

of people say they don’t, but we all want to feel useful, skilled, and

knowledgeable. This should always be a consideration when creating and

implementing an on-the-job training program. Training can be looked at two

different ways. Employees can see it as an opportunity to expand their

skillsets and advance their careers, or they can see it as an indictment of

their current skill and way of working. Trainers always need to aim for the

former response. This is especially true for Kaizen training. Kaizen is a

Japanese word that means to continuously improve the way you work, from day to

day, and in small increments. If trainees can’t see this as an opportunity to

advance themselves, they will not be able to truly grasp the Kaizen concept.

{ Image Credit = bbasicsllc }

For starters, it is often said that “Kaizen

comes from within.” That might sound like a lot of new-age mumbo-jumbo, but it

serves a very practical purpose. Anyone who has tried to reform a workplace

knows that improvements dictated from above rarely stick. Not only is it harder

to get support for such improvement initiative, they are also harder for

employees to learn, remember, and sustain. If, on the other hand, employees

discover problems and implement solutions using their own expertise, they will

develop improvements that they understand and support from the inside out.

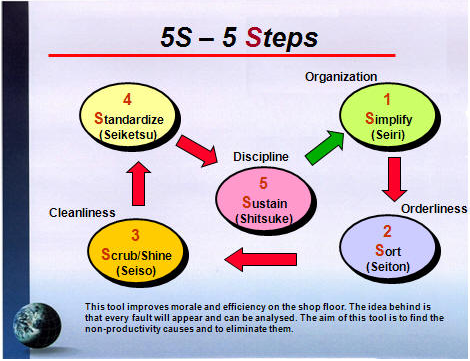

Even if you just set out to “do some 5S”, Kaizen

training is important. Kaizen is not just another tool in the Lean tool

belt; it is a vital element of every Lean methodology. If you are conducting Lean

training for TPM, SMED, or the more well-known 5S,

you will need a foundation of Kaizen to build your program upon. No Lean system

can sustain itself without Kaizen. To sustain a program in the Lean sense is

not just about maintaining the standards; it is about improving and building

upon the standards. If employees view training as a long detention in a

classroom, they will not develop the engaged and self-motivated mindset that

makes continuous improvement possible.

Lean and its underlying philosophy of Kaizen support and develop standards, but that doesn't mean that these improvement methodologies themselves are a standard process. Every company is different, and knowing yourself, your team, and your objectives is a prerequisite for the kind of company Kaizen culture that Lean organizations demand. Who wouldn’t want to work for a company where everyone is encouraged to give their input and change for the better?

Lean and its underlying philosophy of Kaizen support and develop standards, but that doesn't mean that these improvement methodologies themselves are a standard process. Every company is different, and knowing yourself, your team, and your objectives is a prerequisite for the kind of company Kaizen culture that Lean organizations demand. Who wouldn’t want to work for a company where everyone is encouraged to give their input and change for the better?

No comments:

Post a Comment